A brilliant idea

With endless

Possibilities

The principle of Sensor Line’s fiber optic sensors is as simple as ingenious: under load, the optical transmittance decreases. These changes are detected by an opto-electronic interface and then transformed into signals for traffic data processing.

Benefits

- Cheapest permanent sensor installation on the market

- No mechanical parts

- Adapts to pavement contour

- Optimized embedding materials from Sensor Line

- Light-weight and compact sensor implementation

- Minimum sensitivity to lateral pressure

- Ultra-fast, true DC response

- Outstanding trigger accuracy

Microbending

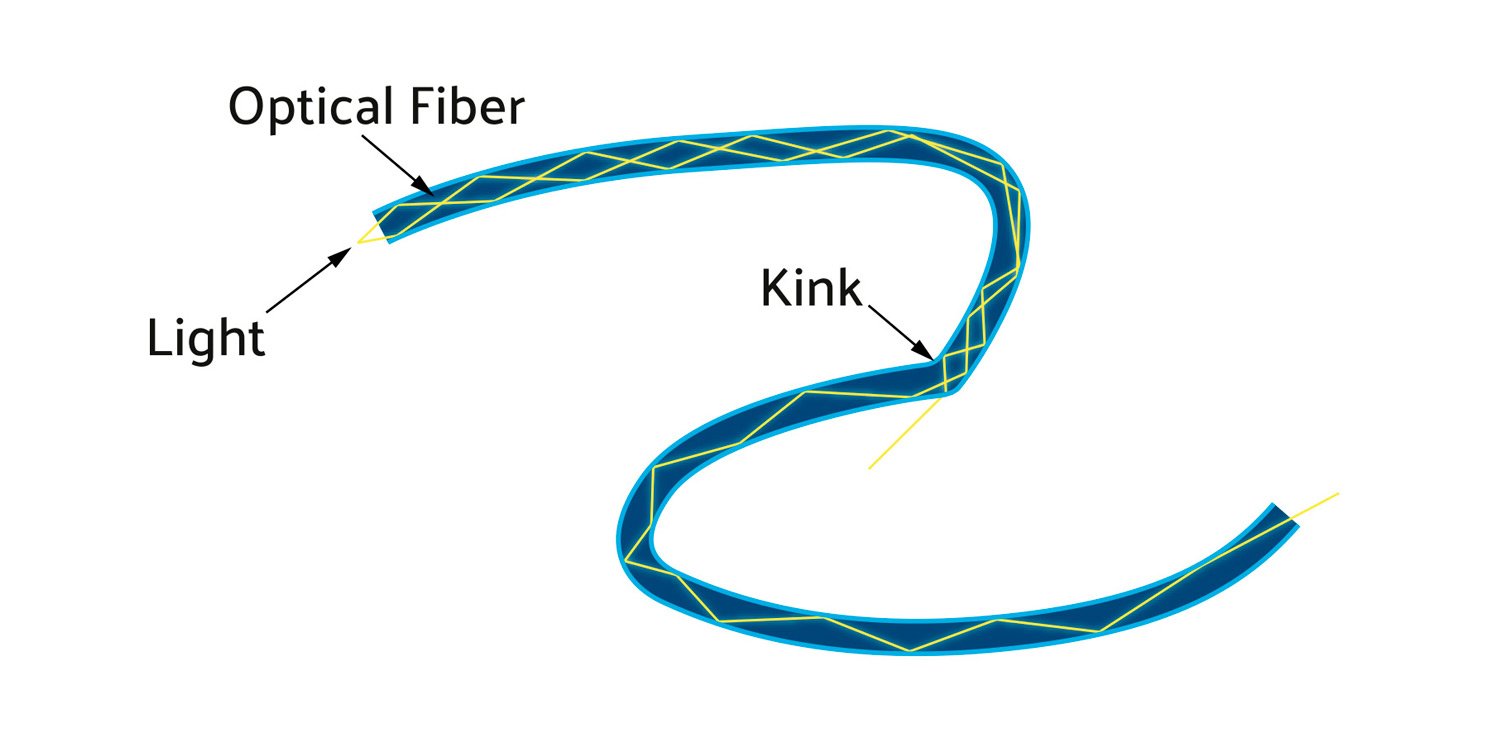

An optical fiber has a glass core surrounded by a cladding of lower refractive index. Light traveling inside the core cannot enter the cladding but rather is reflected without any loss. However, guiding light over long distances in this manner requires the fiber to be even-shaped and straight and the refractive index to be very uniform. Stressing the fiber at one point not only causes a kink but also creates changes in the refractive index, thus severely violating both these requirements. Light then escapes from the fiber core. This loss can be measured as a decrease in the optical power arriving at the fiber’s end. This is the principle used inside of Sensor Line’s fiber optic sensors. Unlike other fiber optical sensing principles, it does not require a specially treated fiber or any additional optical components.

A constant quantity of light is being guided along an optical fiber. At moderate curvatures light loss is hardly noticeable. Below a certain bend radius light loss grows dramatically. Light exits due to “microbending”. The quantity of remaining light varies according to the magnitude of the “microbending” effect and can be easily measured with a simple detector.